Managing waste effectively in industrial settings requires a well-planned recycling system.

Warehouses, factories, and manufacturing sites generate high volumes of many waste streams from their production & distribution activities as well as from their offices and canteens. This can include plastic packaging, paper & cardboard, metals, household waste items such as food, plastic bottles & drink cans, glass bottles, non recyclables as well as hazardous waste..

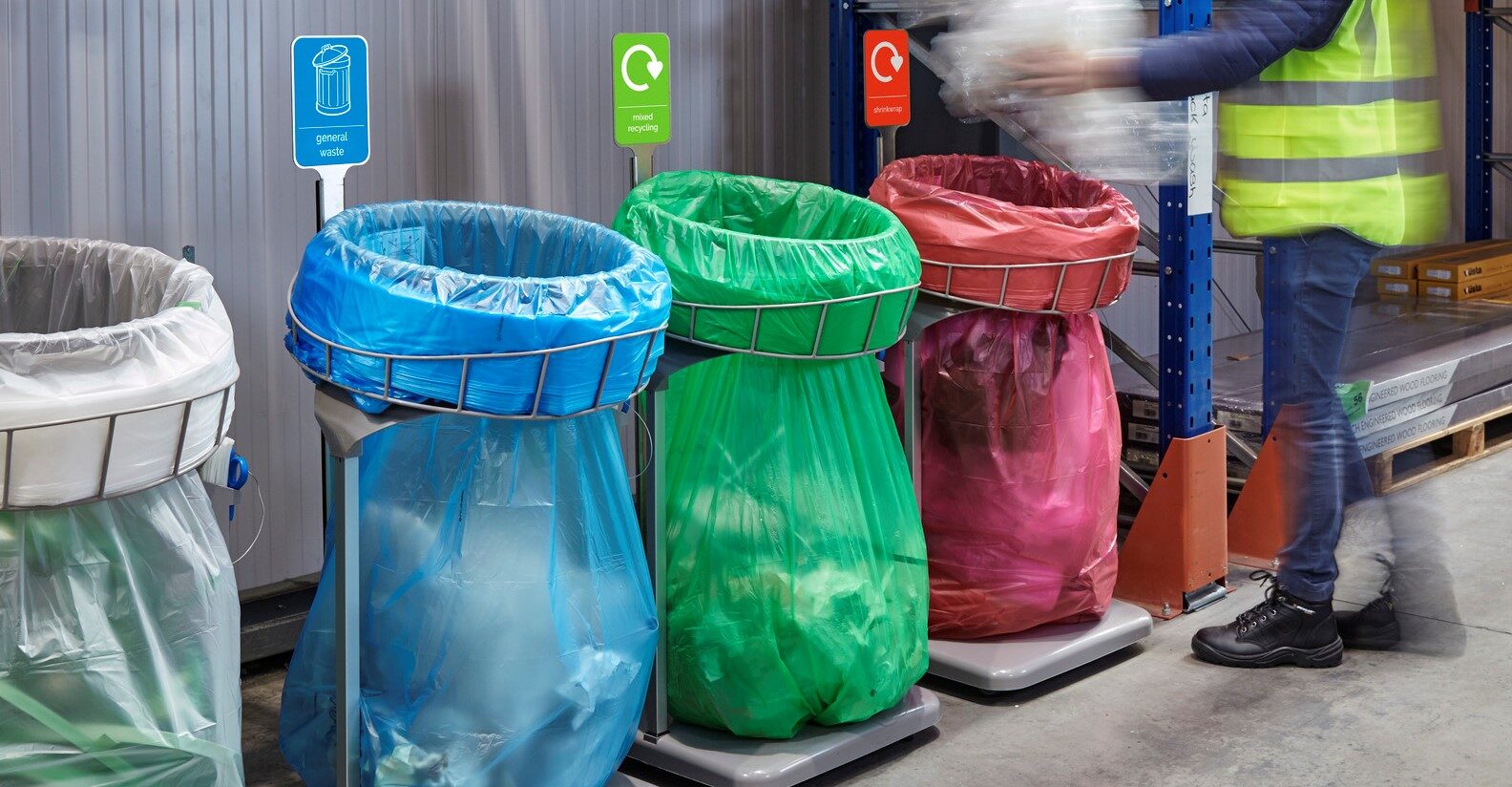

Without the right number of well placed recycling stations and clear signage, waste can end up in the wrong waste streams causing contamination, increasing general waste and pushing up collection costs… not to mention the decrease in recycling rates that leads then to increase in carbon footprint and environmental impact.

A structured approach helps keep operations smooth, reduces environmental impact, and assures compliance with waste management regulations.

Understanding Waste Streams in Warehouses, Manufacturing, and Industrial Sites

Different facilities produce unique types of waste that require specialised recycling solutions:

Warehouses & Distribution Centres

Large amounts of cardboard, soft plastic pallet wrap, plastic strapping, label backing paper, wooden pallets, and packaging waste.

Manufacturing & Industrial Sites

Food waste, scrap metal, plastic parts, cardboard, hazardous & chemical waste, glass, wood, concrete, plaster etc.

Each environment requires a plan and a structured approach to ensure waste is disposed of responsibly and as much as possible is recycled with minimal contamination.

Discover hygienic and time saving manufacturing solutions.

Common Recycling Challenges in Warehouses and Manufacturing

Warehouses and manufacturing facilities often struggle with waste management due to a few key issues:

Contamination & Improper Sorting – Mixing materials like food waste with recyclables can render entire batches contaminated and therefore non-recyclable. Employees may place materials in the wrong station due to unclear signage

High Waste Volumes – Warehouses generate large amounts of cardboard and plastic, while manufacturing sites produce scrap metals and defective parts, all requiring frequent disposal.

Get started with industry-focused recycling engagement training sessions.

Lack of Education & Knowledge – Poor recycling training during the onboarding and induction of new staff and lack of ongoing education for existing staff on the importance of correct recycling on site can lead to contamination and an increase in General Waste. In manufacturing, improper disposal of hazardous waste can create safety risks.

Limited Space for Recycling Stations – Warehouses often have packed storage areas, making recycling station placement a challenge. Manufacturing sites must fit disposal stations within busy production lines.

Irregular Waste Disposal Schedules – When waste collection is inconsistent, recycling stations can overflow or remain underutilised, affecting efficiency and causing recyclables to be stored in other waste containers such as General Waste .

Improve your recycling infrastructure with tailored stations for your specific needs.

How to Select the Right Recycling Stations

Choosing effective recycling solutions ensures waste is managed efficiently, reducing costs and improving sustainability.

Get started by:

-

Analysing Waste Generation Points

Examine where waste is produced in your facility. In warehouses, focus on loading docks and storage areas. In manufacturing sites, assess production lines and material handling zones. Place waste and recycling stations in convenient locations where employees can easily access them without disrupting workflow.

-

Choosing the Right Recycling Station (Types and Capacities)

Select recycling stations designed to handle the specific waste types your facility generates. For warehouses, durable stations for cardboard, plastic wrap, and pallet waste work best. Manufacturing sites need specialised stations for metals, plastics, and hazardous materials. Ensure recycling stations are large enough to handle daily waste volumes without frequent emptying.

-

Using Clear Labels and Signage

Clearly labelled stations reduce recycling confusion, improve waste sorting and reduce contamination. Use large, bold labels and colour coding to make it easy for employees to dispose of waste correctly. Visual guides showing examples of what belongs in each station can further reinforce proper use.

-

Training Employees on Recycling Best Practices

Effective recycling depends on employee participation. Conduct training sessions to explain the importance of sorting waste correctly and demonstrate how to use the recycling stations. Periodic refreshers help maintain compliance and reinforce positive habits.

-

Maintaining Regular Waste Collection and Monitoring

Schedule frequent waste collection to prevent overflow. Assign staff to monitor station usage and address contamination or improper disposal issues. Regular audits can help identify inefficiencies and improve the recycling process over time.

Recycling Solutions for Warehouses and Manufacturing Facilities

Unisort offers a range of recycling stations designed for high-demand environments. Our solutions make it easy to manage different waste types efficiently:

Unisort Liner Recycling Stations

A large variety of floor-standing recycling stations that can be easily wheeled around (or not) and be combined with our continuous liner system for high-capacity waste collection with minimal liner changes, ideal for fast-paced manufacturing environments.

Traditional waste bags lead to unnecessary plastic waste, with excessive overhang, underfilled bags, and inefficient emptying schedules..

The Unisort Liner system eliminates these inefficiencies by ensuring only the necessary amount of liner is used each time, reducing plastic consumption by up to 80% and significantly cutting CO₂ emissions.

Benefits of the Unisort Liner system:

- Up to 80% plastic and CO₂ savings compared to standard bin bags.

- No more excessive overhang. Every liner is efficiently filled with no wasted plastic

- Fewer bag changes, reducing labour time by up to 38% and improving workflow efficiency.

- Thinner yet 3-4x stronger liners, using a special 3-ply LDPE formula to handle heavy or sharp waste without splitting.

- Faster, easier waste disposal. Emptying and relining takes just 30 seconds, with the next liner always ready to go.

Unlike standard bin liners, our Unisort Liner system adapts to your waste volume, eliminating unnecessary plastic use. The system’s high-strength yet thinner liners further reduce material consumption without compromising durability.

By switching to the Unisort Liner system, your business can save plastic, cut costs, and boost efficiency, all while reducing its environmental impact.

Jumbo Warehouse Recycling Holders & Sacks

Designed for high-volume waste collection, these sturdy recycling bin holders fit 1400L jumbo recycling sacks, making them ideal for warehouses, production lines, and packing areas. They efficiently collect materials like plastic film, shrink wrap, polystyrene, and bottles, helping businesses separate recyclables with ease. Also available in 400L capacity.

The clear liners improve visibility, ensuring waste goes into the correct stream, increasing staff accountability. Lightweight and easy to assemble, these holders are specifically designed to be used around pallets, streamlining waste sorting in busy industrial environments.

Using jumbo recycling sacks reduces general waste collections, cutting costs while also creating opportunities to bale and sell recyclable plastic waste. With a low initial investment and a simple setup, these holders help businesses save time, space, and money while improving sustainability efforts.

Unisort Dual Waste Collection Carts

Built for efficiency, the Unisort Dual Waste Collection Cart features two 150L durable vinyl bags, making it perfect for segregating waste in industrial and warehouse environments. Its high-capacity design handles large waste loads while maintaining a reliable, long-lasting performance.

ace when not in use, and four swivel castors ensure easy maneuverability, even in busy workplaces. Easy to clean and available in a 300L version, this cart simplifies waste collection while improving recycling efficiency.

Our advanced recycling systems are designed to streamline waste processes, reduce carbon footprint, and achieve substantial plastic waste reduction and up to 80% savings in CO2 emissions.

With Unisort’s industry-specific solutions, recycling becomes a seamless part of daily operations. Investing in the right recycling stations keeps workplaces cleaner, reduces waste disposal costs, and contributes to a more sustainable future.

An effective recycling system helps warehouses, manufacturing factories, and industrial facilities manage waste efficiently while reducing environmental impact.

By identifying waste streams, addressing common recycling challenges, and selecting the right recycling stations, businesses can create a cleaner, safer, and more sustainable workspace.

Unisort’s specialised recycling stations offer practical solutions for industries that need reliable waste management tools. Contact us to start improving your recycling process today.