Effective handwashing is paramount in any food production scenario – for personal health and food safety. But are you missing a trick during this straightforward task? In this article, I’ll explore how businesses can further optimise their existing handwashing process to safeguard their assets (brand, reputation, production, staff and customers).

The Why, What, Who, When and Where of Handwashing – a.k.a The 5 W’s

#1. Why?

According to Public Health England, up to one million cases of food-borne illnesses are reported in the UK each year, hospitalising around 20,000 people and killing around 500. As these figures are based on public notices issued by the authority they are likely to only represent a small proportion of the true figure.

#2. What?

It may seem obvious, but you know what happens to those who assume (the phrase ass out of you and me spring to mind). So, just to be clear, the what is your hands. Protection of all surfaces that could make contact with food also needs safeguarding, from your hair, face, shoes, clothing, surfaces etc etc

#3. Who?

Again, not wanting to be nicknamed Eeyore, that’s everyone (with the exception of no-one) who plays a part in the food processing journey – and not just those who come into direct contact with food.

#4. When?

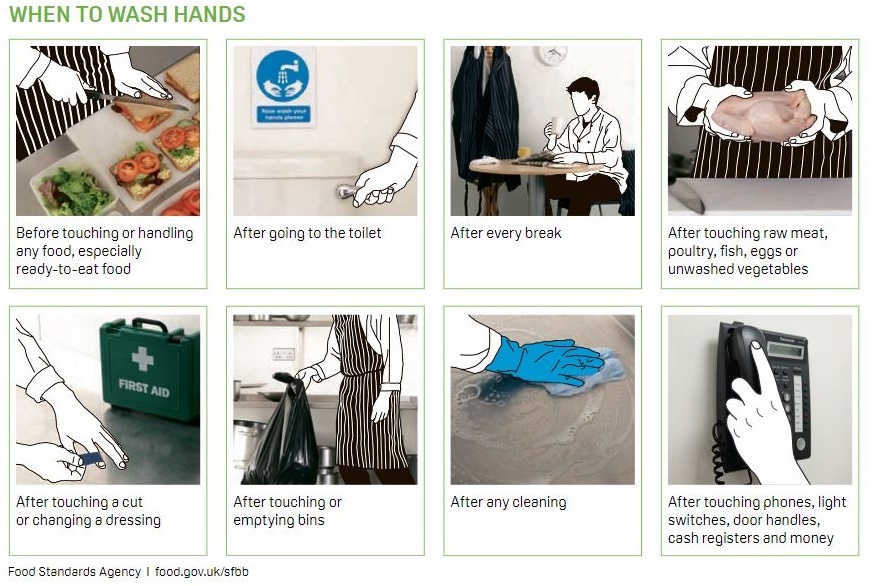

As featured in the Food Standards Agency campaign SFBB (Safer food, better business), you should wash your hands;

- Before touching or handling any food, especially ready-to-eat food

- After going to the toilet

- After every break

- After touching raw meat, poultry, fish, eggs or unwashed vegetables

- After touching a cut or changing a dressing

- After touching or emptying bins

- After cleaning

- After touching phones, light switches, door handles, cash registers and money

#5. Where?

Where hands are washed can be just as significant as the actual practice. Handwashing should be limited to certain designated areas called handwashing stations. And this is where businesses could further optimise an existing process to safeguard their assets even further.

Shoe cleaning can be a common pain point for those in food production. A critical cleaning process often the victim of human avoidance. By installing a cleaning solution in an area already designated as a critical area makes sense.

This human avoidance (or shortcut) solution has been adopted by major brands within the food industry. ProfilGate, originally designed from the belief that clean production is the pre-requisite for Industry 4.0. Complete with 11 models plus footwear cleaning machines, the Aqua and Go are most commonly used in the handwash scenario.

ProfilGate aqua

|

ProfilGate go

|

|

|

ProfilGate is also proven to;

|

As used by:

|

Need to find out more? DOWNLOAD the brochure.